Earlier this month I was fortunate enough to join Paul Goodhead from bit-tech.com on a tour of our GIGABYTE motherboard factory out in Taipei County, and what an eye opening experience it was. Motherboards have come a long way in the last few decades, adding more and more features with improvements to durability and longevity, so much so that motherboard manufacturing now involves bleeding-edge technology and manufacturing processes. Nowhere is this more true than at our Nan-Ping factory just outside Taipei in Northern Taiwan where GIGABYTE’s top tier motherboards products are manufactured, thoroughly tested and then packaged ready to be shipped off to DIY PC retailers around the globe.

Paul’s written a great article which details every step of the process with lots of photos of the production line itself. If you’ve ever wondered just how a motherboard is created, check out the article for yourself. Here are some images to whet your appetite:

Did you know?

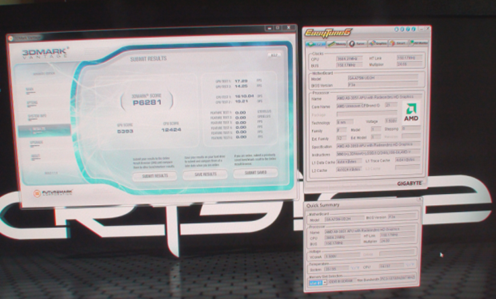

GIGABYTE is the only DIY PC motherboard manufacturer that still has a manufactures in Taiwan. This gives us the edge in a number of areas. For example it means that top-tier motherboards products that showcase new technologies and bleeding edge features can be thoroughly honed, tuned and debugged by a relatively small, yet highly capable team of experts that have been together for many years. Believe me when I say that is virtually impossible to replicate in China and is one of our core strengths as a company. Also, when labor shortages hit production lines in Mainland China, our Taiwan factory can help absorb up to 40% production. While on the factory tour I was also reminded that we make every effort to make sure that all boards are tested to the limit, using the most stringent quality control procedures that actually help reduce our RMA rates.

Check out Paul’s full article on bit-tech.com.

Chinese version of this article can be found here.